Future Trends in Electrical Safety: Best NH Fuse Type Disconnectors Shaping the 2025 Industry Landscape

As we look towards 2025, the landscape of electrical safety is poised for significant advancements, particularly with the rise of NH Fuse Type Disconnectors.

According to the latest industry report by MarketsandMarkets, the global market for electrical safety equipment is projected to reach $52.9 billion by 2025, driven by increasing regulatory requirements and the growing emphasis on workplace safety.

NH Fuse Type Disconnectors are at the forefront of this transformation, offering enhanced protection against overloads and short circuits, essential in a world that demands higher reliability from electrical systems.

The integration of smart technology and innovative design in these disconnectors will not only improve safety but also enhance operational efficiency, making them a critical component in future electrical installations.

As we explore these trends, the role of NH Fuse Type Disconnectors will undeniably shape the industry standards for electrical safety, providing a robust foundation for advancements in technology and regulation compliance.

According to the latest industry report by MarketsandMarkets, the global market for electrical safety equipment is projected to reach $52.9 billion by 2025, driven by increasing regulatory requirements and the growing emphasis on workplace safety.

NH Fuse Type Disconnectors are at the forefront of this transformation, offering enhanced protection against overloads and short circuits, essential in a world that demands higher reliability from electrical systems.

The integration of smart technology and innovative design in these disconnectors will not only improve safety but also enhance operational efficiency, making them a critical component in future electrical installations.

As we explore these trends, the role of NH Fuse Type Disconnectors will undeniably shape the industry standards for electrical safety, providing a robust foundation for advancements in technology and regulation compliance.

The Evolution of NH Fuse Type Disconnectors: A Historical Perspective

The history of NH fuse type disconnectors is marked by significant advancements that have greatly improved electrical safety and efficiency. Originating in the mid-20th century, these devices were developed to provide a reliable means of interrupting electrical circuits while ensuring minimal downtime. Initially designed for industrial applications, the NH fuse's robust construction and ease of maintenance quickly led to widespread adoption across various sectors. As the demand for safer and more efficient electrical systems grew, innovations in materials and technology further enhanced the performance and reliability of NH fuse type disconnectors.

In the following decades, the evolution of NH fuses mirrored the rapid technological advancements seen in the electrical industry. Developments such as improved fuse designs and the integration of smart technologies have transformed traditional disconnectors into intelligent devices capable of real-time monitoring and diagnostics. This evolution not only increases safety but also optimizes the overall functionality and operational efficiency of electrical systems.

As we approach 2025, the ongoing enhancements in NH fuse type disconnectors will undoubtedly play a critical role in shaping a safer and more efficient electrical landscape.

Innovative Technologies Driving NH Fuse Disconnectors in the Future

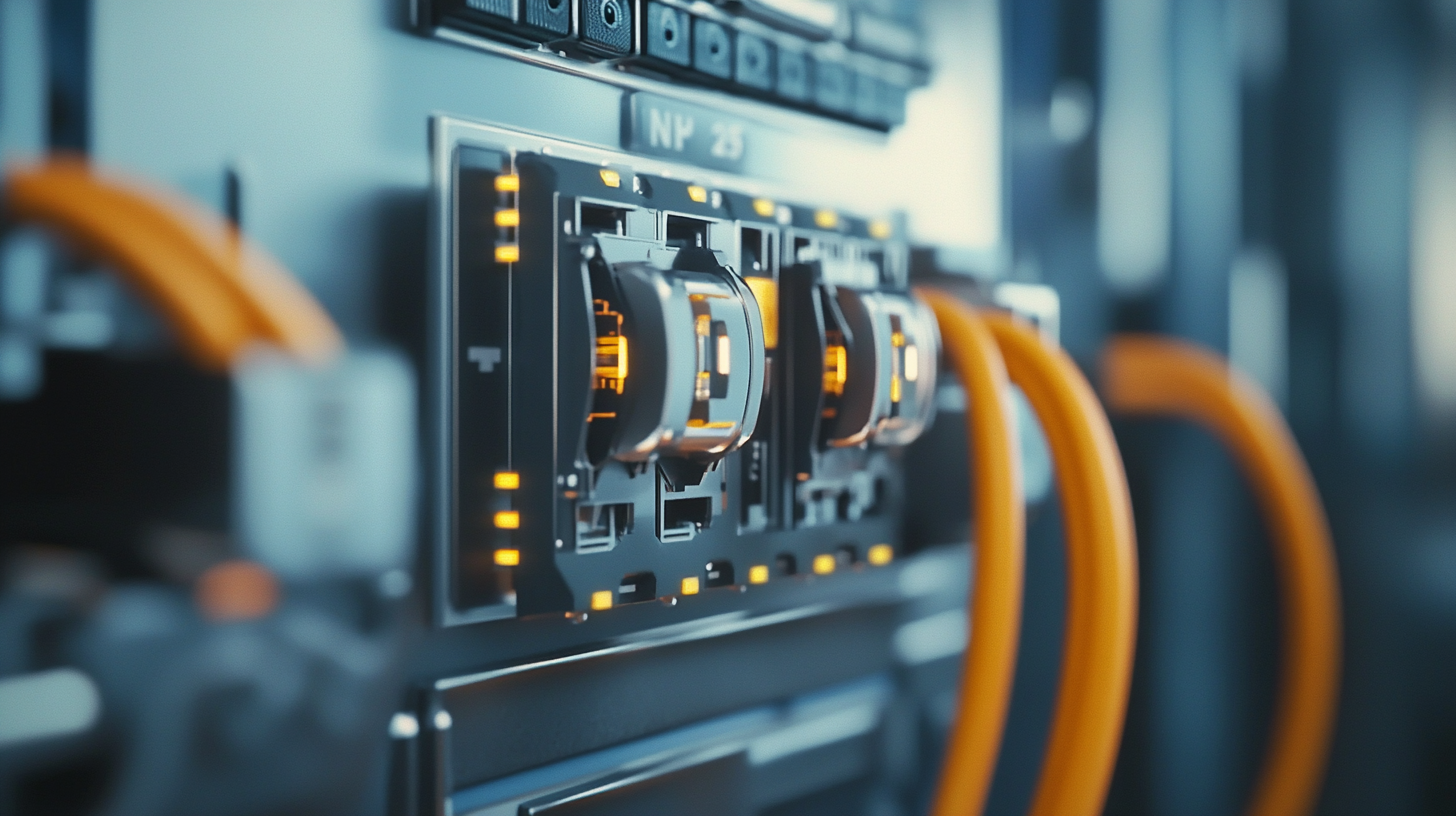

The future of electrical safety is being shaped by innovative technologies that are driving the development of NH fuse type disconnectors. These devices are vital components in modern electrical systems, ensuring both safety and reliability. As we approach 2025, advancements in smart technology, such as IoT integration and enhanced materials, are elevating the performance standards of disconnectors. For instance, smart NH fuse disconnectors can now monitor electrical loads in real-time, providing invaluable data that allows for proactive maintenance and quicker response to fault conditions.

Moreover, advancements in materials technology are leading to more robust disconnectors capable of withstanding harsh environments and high-stress conditions. New insulating materials with superior thermal stability and durability are enhancing the safety and efficiency of NH fuse type disconnectors. Additionally, the push for sustainability is fostering the creation of eco-friendly components, which not only reduce environmental impact but also meet the evolving regulatory requirements. Together, these innovations will not only improve electrical safety but also play a critical role in the overall reliability and efficiency of electrical systems in the coming years.

Key Benefits of Implementing Advanced NH Fuse Disconnectors in Electrical Safety

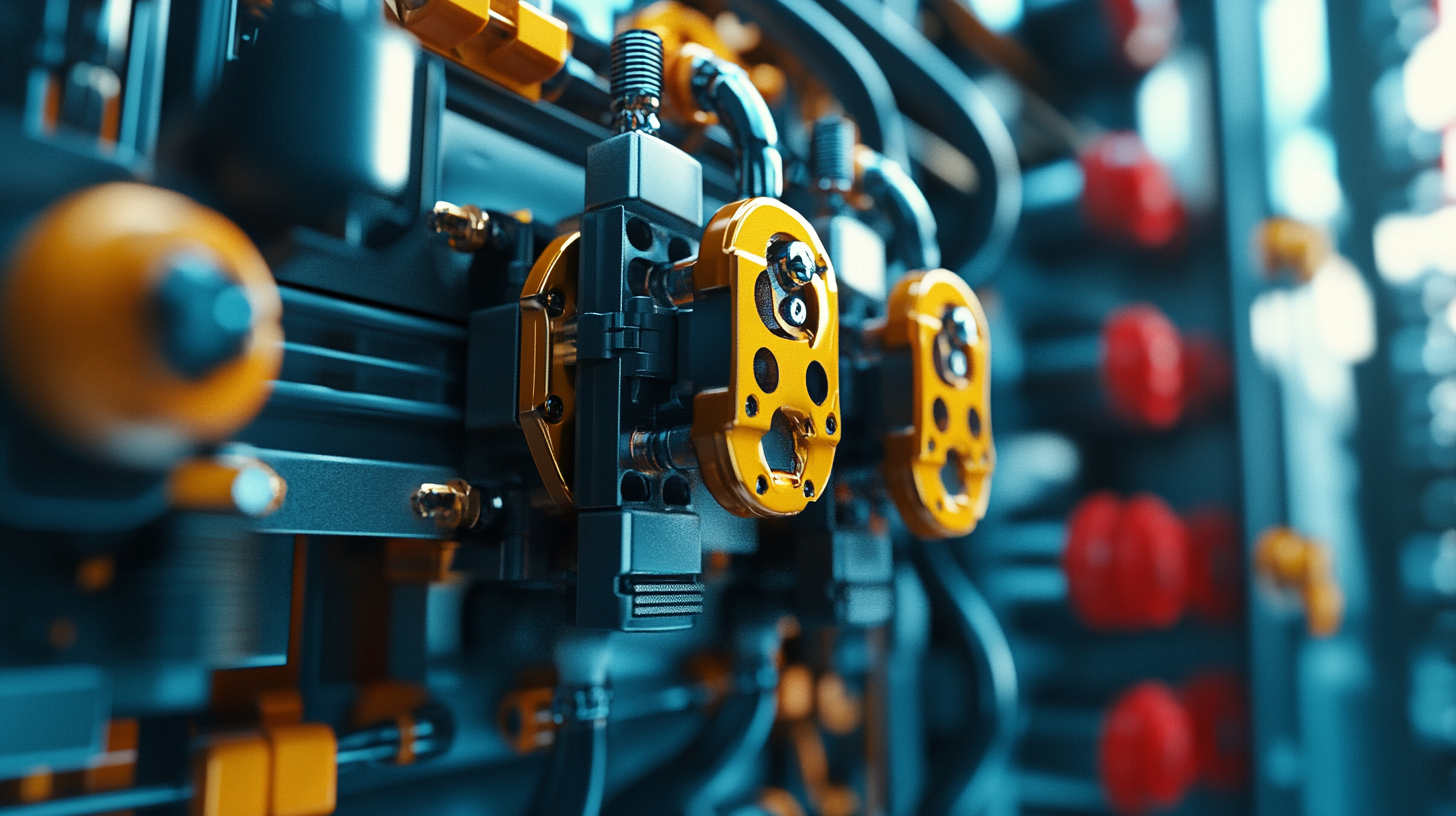

In the rapidly evolving world of electrical safety, the implementation of advanced NH fuse disconnectors presents a significant leap forward in protecting both equipment and personnel. These disconnectors are designed to provide reliable isolation and protection in various settings, reducing the risk of electrical faults and ensuring compliance with safety regulations. By integrating advanced features such as enhanced fault current interruption and improved thermal management, NH fuse disconnectors not only safeguard electrical systems but also extend the lifespan of valuable machinery.

Furthermore, these disconnectors offer crucial benefits in terms of operational efficiency and maintenance. With their ability to isolate faults quickly, NH fuse disconnectors minimize downtime, allowing businesses to maintain productivity without extensive disruptions. The simple yet effective design facilitates easier maintenance and replacement, resulting in lower operational costs. As the industry shifts towards a more safety-conscious environment, investing in state-of-the-art NH fuse disconnectors is essential for companies aiming to stay ahead of the curve in electrical safety technology.

Regulatory Changes Impacting NH Fuse Type Disconnectors by 2025

The landscape of electrical safety is poised for significant transformation by 2025, particularly due to upcoming regulatory changes impacting NH fuse type disconnectors. These devices play a crucial role in circuit protection and safety, ensuring that systems can be isolated quickly in the event of a fault. As regulations evolve, manufacturers and users must stay informed about compliance standards to foster a safer working environment.

One important tip for those involved in the disconnect switch market is to closely monitor the latest regulatory guidelines. Staying ahead of compliance requirements not only enhances safety but can also provide a competitive edge in the industry. Additionally, investing in training and development for staff about these changes will ensure effective implementation and understanding of new technologies and standards.

Another critical aspect to consider is the type of disconnect switch being used. Fused disconnects provide an added layer of protection that may become increasingly necessary as regulations tighten. Regular maintenance and assessment of these devices will not only prolong their lifespan but also guarantee they operate within the safety measures prescribed by new regulations.

Being proactive in equipment management can lead to improved operational efficiency and reduced risks associated with electrical faults.

Case Studies: Successful Implementation of NH Fuse Disconnectors in Various Industries

The implementation of NH fuse disconnectors has demonstrated significant effectiveness across various industries, showcasing their vital role in electrical safety. In the manufacturing sector, a leading automotive plant adopted NH fuse disconnectors during a major electrical overhaul. The decision resulted in enhanced protection of critical machinery and reduced downtime. Installation of these disconnectors facilitated faster fault isolation, allowing maintenance teams to address issues promptly, thereby improving overall operational efficiency.

In the renewable energy sector, a solar power facility benefited from the use of NH fuse disconnectors in its grid connection system. By integrating these devices, the plant achieved a higher level of reliability and safety in handling transient faults commonly associated with solar panels. The case study revealed a marked decrease in maintenance costs and an increase in energy production efficiency, as the disconnectors played a crucial role in protecting the systems, ensuring uninterrupted power delivery to the grid.

These success stories highlight the versatility and importance of NH fuse disconnectors in promoting electrical safety across different sectors. As industries look towards 2025, the trend of incorporating these advanced safety solutions will likely continue, driving innovations in electrical infrastructure and safety protocols.